skills used/developed

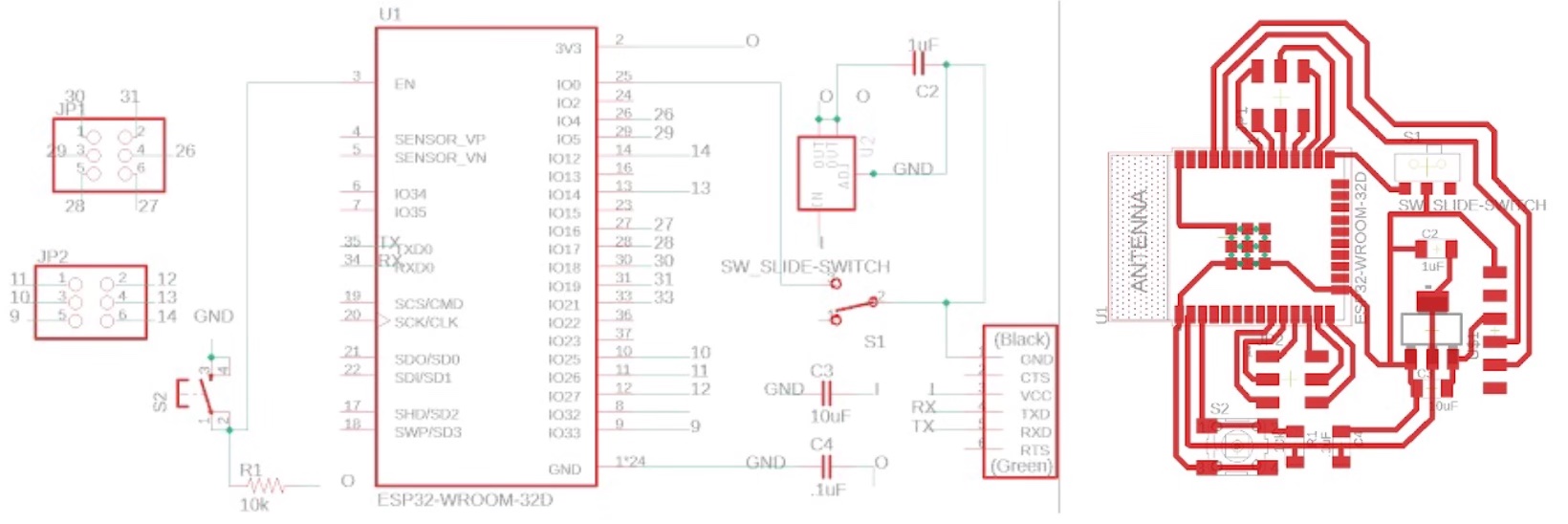

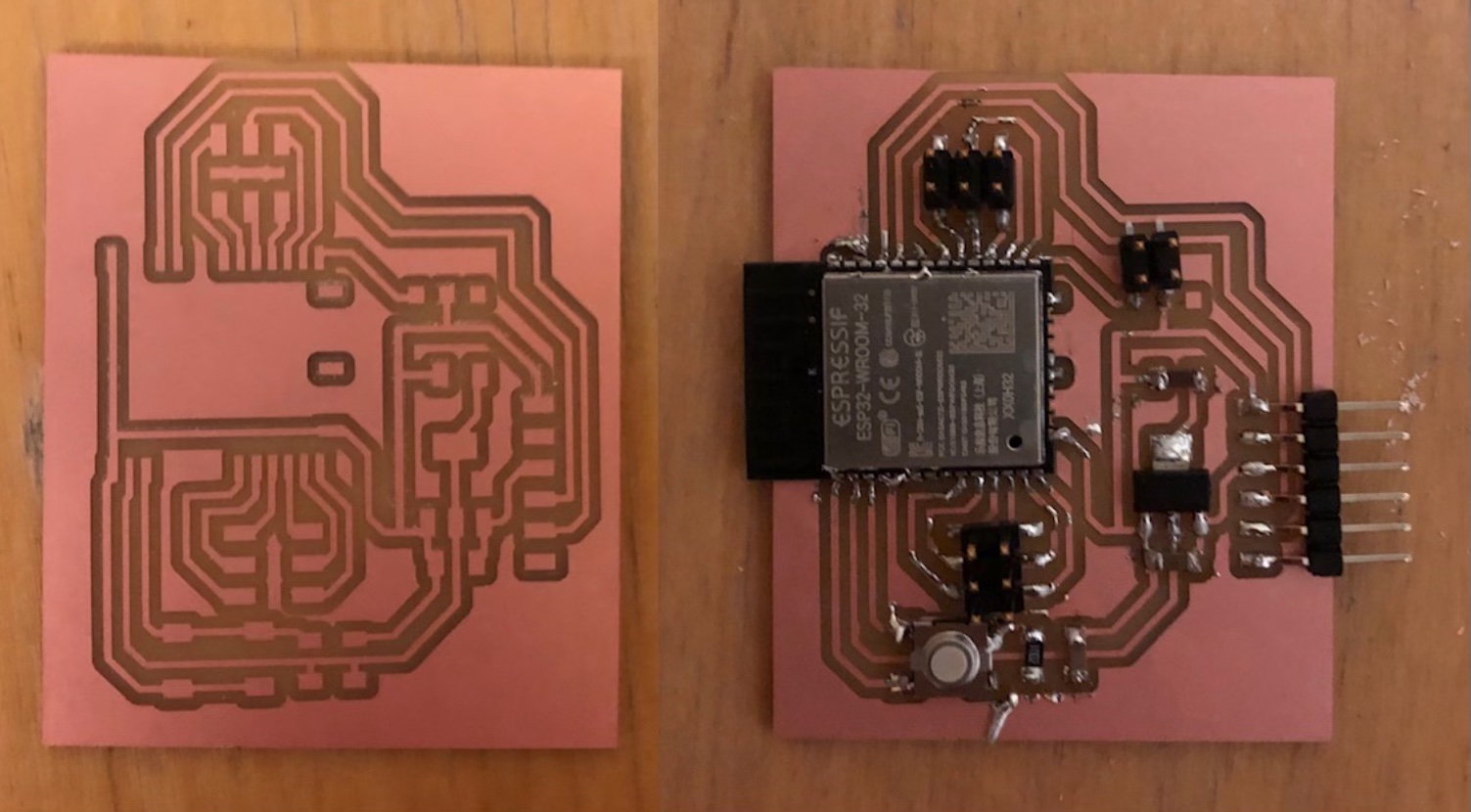

- PCB design and fabrication

- sensors and actuators

- mixed-signal instrumentation

- embedded processing

- wired and wireless communications

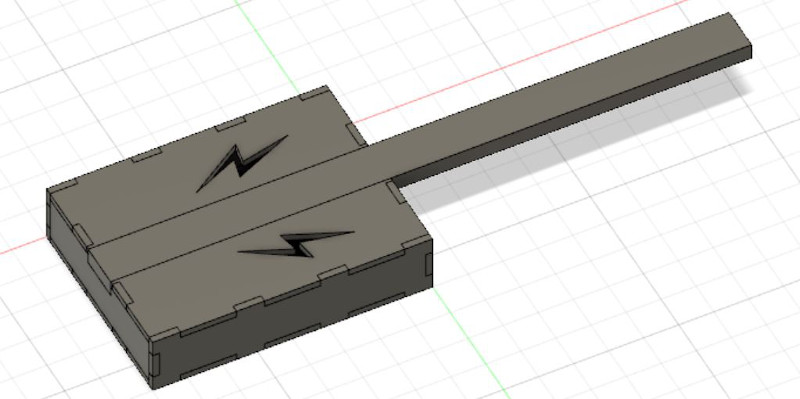

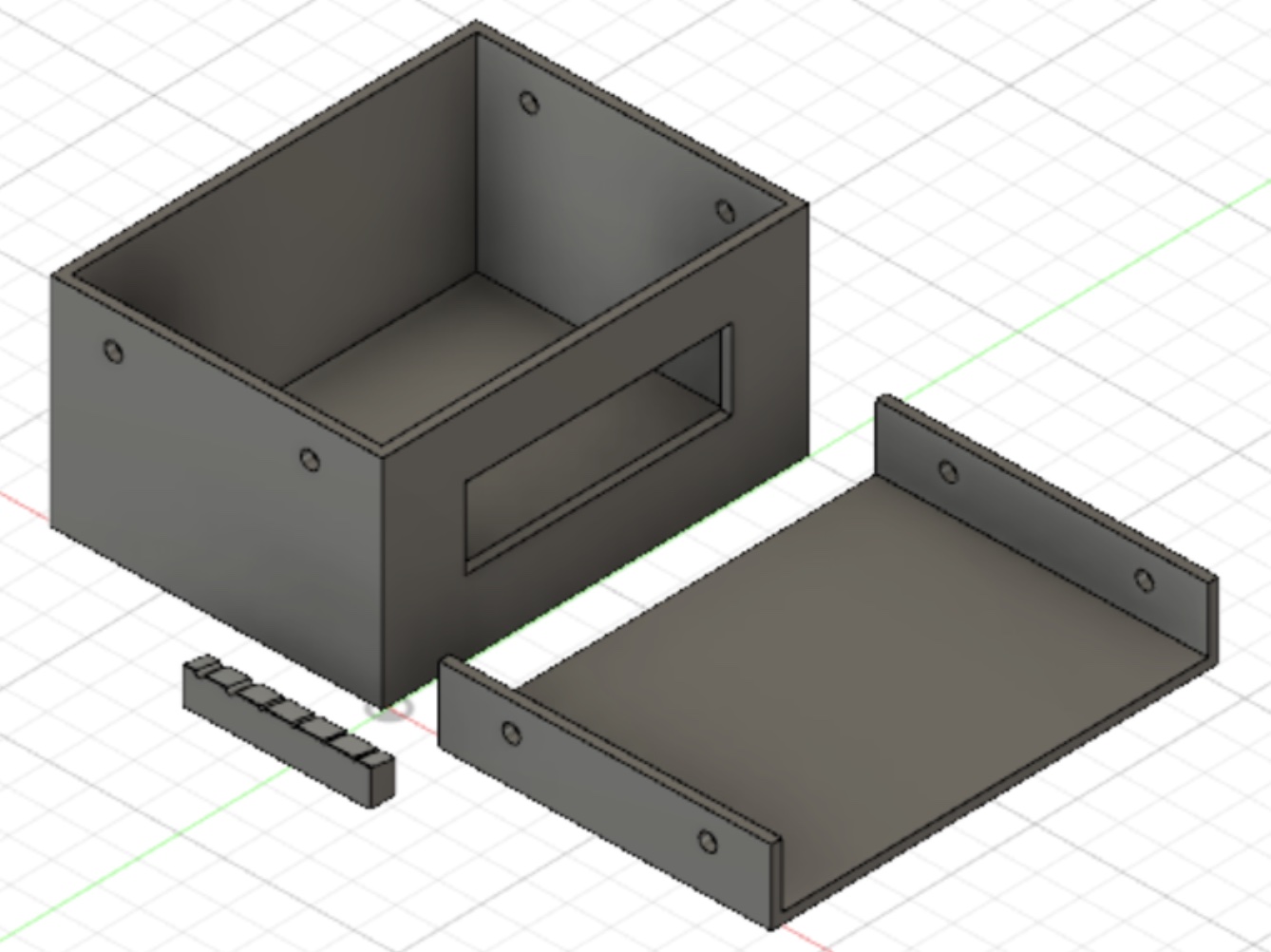

- CAD/CAM/CAE

- NC machining

- laser and waterjet cutting

- 3-D printing and scanning

- molding and casting

- Arduino